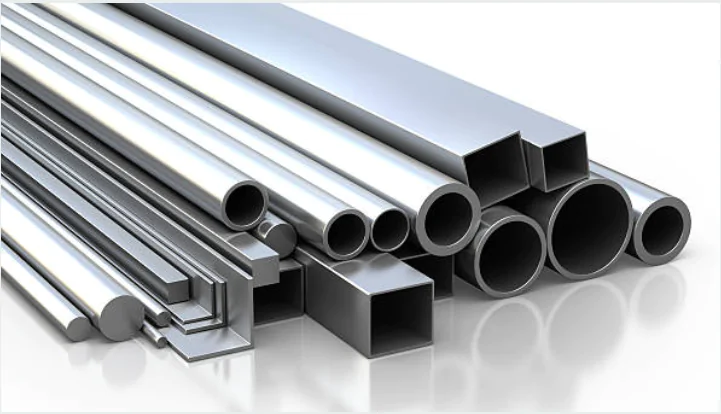

Stainless steel tubes are widely used components in civil, commercial and industrial construction projects. Due to their characteristics, these products are recognized in the market for their high durability, resistance and quality.

Stainless steel is a material that resists contact with extreme environments and corrosive substances, preserving its aesthetic appearance and physical integrity to offer insulation and safety in final product applications.

This is because the coating process carried out during steel manufacturing gives them all the characteristics that the material must have to be applied in places with humidity, exposed to the effects of time and conduction systems for corrosive materials and chemical fluids that must be isolated from the environment. contact with people and other environments in a building.

In addition, stainless steel is extremely versatile and can also be used in civil, commercial and industrial installations, decorative projects and in the creation of a series of products that reach the market, such as the Rectangular Stainless Steel Tube.

When this material is used for the manufacture of stainless steel tube models, it is very important to understand what are the characteristics and differences between the two types of stainless steel tubes that we can find for sale: with seam and without seam. Learn all about seamless and seamless stainless steel tubes and understand when to use each one of them within a project:

● Seam stainless steel tubes

Seam stainless steel tubes are manufactured by welding sheet metal. The ends of the plates are joined and welded using instruments that unite the ends of the material using heat, in order to create different models of steel tubes with their own thicknesses, lengths and diameters.

Quite popular and easily found in the market, the stainless steel tube with seam can be found in applications within the automotive industry, in sugar mills, in the manufacture of machinery and equipment for use in the agriculture sector and in the infrastructure of connections and systems of conduction of fluids and materials.

Its difference compared to seamless tubes is directly related to its manufacturing process, originating components such as Rectangular Stainless Steel Tube models.

● Seamless stainless steel tubes

During their manufacture, the seamless cut stainless steel tube models are made using cylinders that are heated in order to make them hollow, allowing them to be drilled later.

Seamless stainless steel tubes do not undergo welding to obtain a more closed format, which is why the Cut Stainless Steel Tube is recommended for precision applications in piping and systems for conducting materials and fluids under pressure in industries, boilers and hydraulic pistons.

Seamless tube applications are made according to the needs of each project, adapting more to certain cases compared to seam tubes and vice versa.